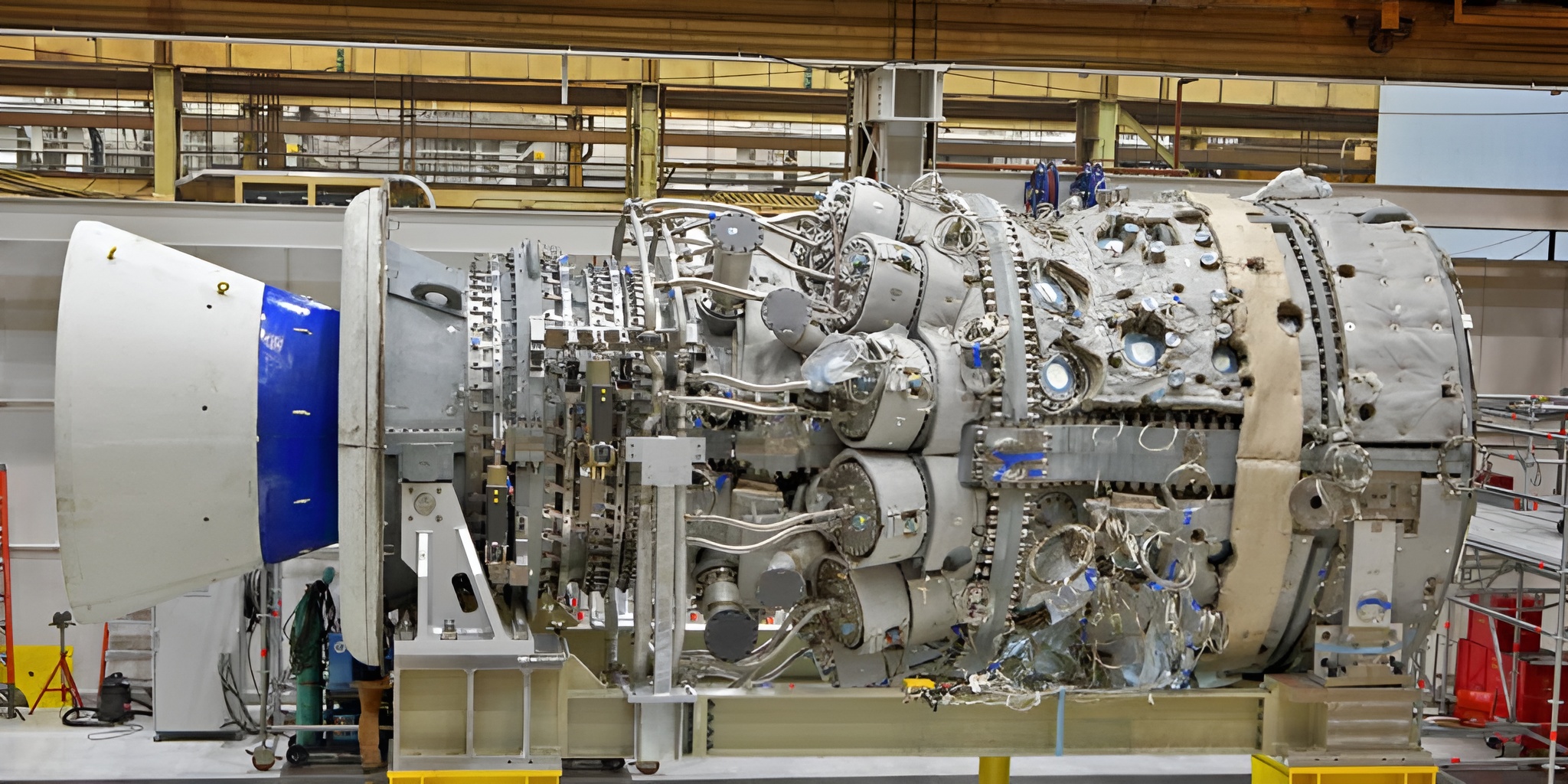

This project leveraged computational fluid dynamics (CFD) and 3D modeling to refine gas‑turbine blade geometries for enhanced aerodynamic performance. By investigating case studies such as GE’s H‑Class and Siemens SGT‑800, blade profiles were iteratively reshaped to minimize flow losses and improve thermal management. The study also explored emergent tools—AI‑based surrogate modeling and additive manufacturing—to accelerate the design loop while tackling integration and certification challenges. Results demonstrated potential efficiency gains of up to 3% and lower turbine outlet temperatures, underscoring aerodynamic optimization as a key enabler for next‑generation gas turbines.